Wiring problems and mistakes are alarmingly prevalent, and their consequences can be dire, posing risks such as short circuits, electric shocks, and even fires. It is crucial to take immediate action to identify and rectify any issues you encounter. Here’s an essential guide to help you identify potential wiring problems and take the necessary steps to ensure safety.

Making Connections Outside Electrical Boxes

Mistake: No electrical box

This refers to the practice of connecting wires without using an electrical box. Electrical boxes serve a vital purpose in protecting connections from accidental damage and containing sparks and heat generated by loose connections or short circuits. Failing to use an electrical box can pose significant safety hazards.

Solution: Add a box

Installing an electrical box to contain the connections and ensure safety. By adding an electrical box, the wires can be properly enclosed and protected. This step is essential for preventing accidents, reducing the risk of electrical fires, and maintaining the integrity of the electrical system.

Cutting Wires Too Short

Mistake: Wires too short

This refers to the issue of cutting wires too short during electrical installations. When wires are cut too short, it becomes challenging to make proper wire connections. Additionally, the likelihood of making poor connections increases, which can be dangerous and compromise the integrity of the electrical system.

Solution: Extend wires

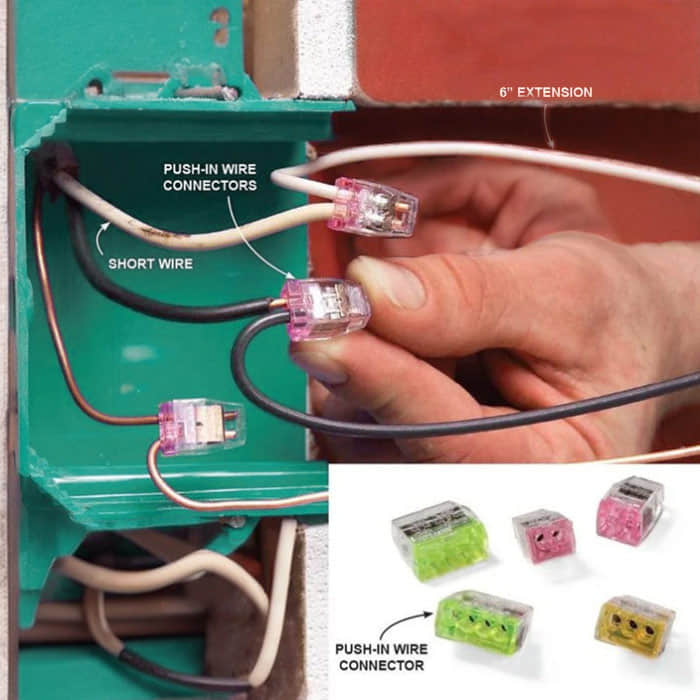

Extending the wires to ensure they have sufficient length for proper connections. By adding 6-inch extensions to the existing wires, individuals can overcome the issue of short wires. This extension provides the necessary length to facilitate easier and more secure wire connections.

The provided photo showcases a specific type of wire connector that is designed to be installed in tight spots, making it easier to extend wires in challenging areas. These wire connectors are typically available in hardware stores and home centers, making them easily accessible for individuals undertaking electrical projects.

Leaving Plastic-Sheathed Cable Unprotected

Mistake: Unprotected cable

This mistake refers to the practice of leaving plastic-sheathed cables exposed in areas between framing members. When a cable is left unprotected, it becomes susceptible to damage. The electrical code mandates the protection of cables in these areas due to the increased risk of harm. Cable is particularly vulnerable when it is run over or under wall or ceiling framing.

Solution: Install a 2 x 2

The suggested solution involves installing a 1-1/2-inch-thick board alongside the exposed plastic-sheathed cable. This board serves as protection and prevents accidental damage. The cable does not need to be stapled to the board. By providing this additional layer of safeguarding, the cable remains shielded from potential harm.

Additionally, the excerpt suggests using metal conduits when running the wire along a wall. Metal conduit offers a higher level of protection compared to plastic-sheathed cable, further reducing the risk of damage.

Poor Support for Outlets and Switches

Mistake: Loose outlet

This mistake refers to switches or outlets that are not securely connected, leading to potential dangers. Loose outlets can move around, causing the wires to loosen from the terminals. This loose connection can result in arcing, overheating, and creating a fire hazard.

Solution: Add rigid electrical box spacers

Fix loose outlets by adding rigid electrical box spacers to create a tight connection between the outlet and the box. These spacers can be purchased at home centers and hardware stores, specifically designed for this purpose. By using these spacers, individuals can ensure a secure and stable connection, minimizing the risk of loose wires and potential hazards.

Installing a Three-Slot receptacle without a Ground Wire

Mistake: No grounding wire

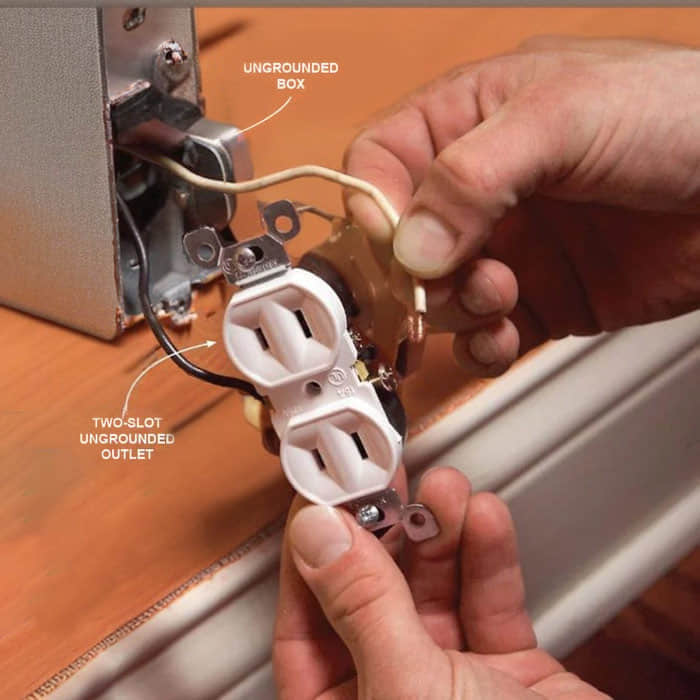

This mistake refers to the absence of a grounding wire in two-slot outlets. It can be tempting to replace them with three-slot outlets to accommodate three-prong plugs. However, this should not be done unless a proper ground is available.

Solution: Install a two-slot outlet

Using a tester to determine if the outlet is grounded. This tester, readily available at home centers and hardware stores, consists of a series of lights that indicate whether the outlet is wired correctly or if a fault exists. By using the tester, individuals can assess the grounding status of the outlet.

If an ungrounded box is discovered with a three-slot outlet, the easiest fix is to replace it with a two-slot outlet. This replacement ensures that the electrical system remains safe and prevents potential hazards.

Recessing Boxes Behind the Wall Surface

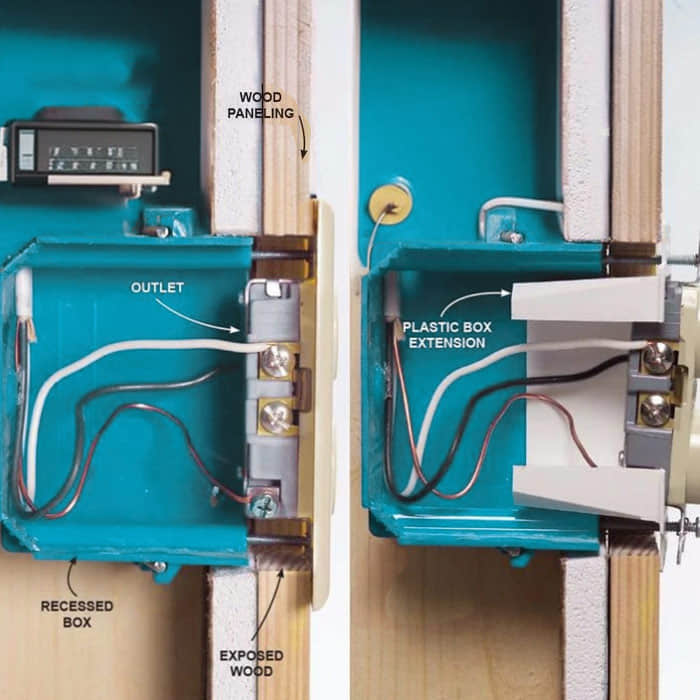

Mistake: Exposed combustible material

This mistake refers to the improper installation of electrical boxes, particularly when they are recessed behind combustible materials like wood. When electrical boxes are not flush with the wall surface, combustible materials are left exposed to potential heat and sparks, creating a fire hazard.

Solution: Add a box extension

The suggested solution involves installing a box extension to ensure that the electrical box is flush with the wall surface. This can be achieved by using a metal or plastic box extension, depending on the type of box being used.

If a metal box extension is used on a plastic box, it is important to connect the metal extension to the ground wire in the box. This can be done using a grounding clip and a short piece of wire, ensuring proper grounding and electrical safety.

By adding a box extension, individuals can eliminate the exposure of combustible materials to potential heat and sparks, reducing the risk of fire hazards.

Installing Cable Without a Clamp

Mistake: Missing clamp

This mistake refers to the absence of clamps to secure cables in electrical boxes. When cables are not properly secured, it can strain the connections and potentially cause damage. In metal boxes, the sharp edges can cut through the insulation on the wires, leading to exposed wires and potential hazards. The specific requirements for cable clamps vary depending on the type and size of the box.

Solution: Install a clamp

The suggested solution involves installing a cable clamp to ensure proper securing of the cables. When installing a clamp, it is important to ensure that the sheathing on the cable is trapped under the clamp, providing a secure connection. Approximately 1/4 inch of sheathing should be visible inside the box.

Some metal boxes come with built-in cable clamps, while others require separate clamps. If the box being used does not include clamps, it is necessary to purchase clamps separately and install them when adding the cable to the box.

Overfilling Electrical Boxes

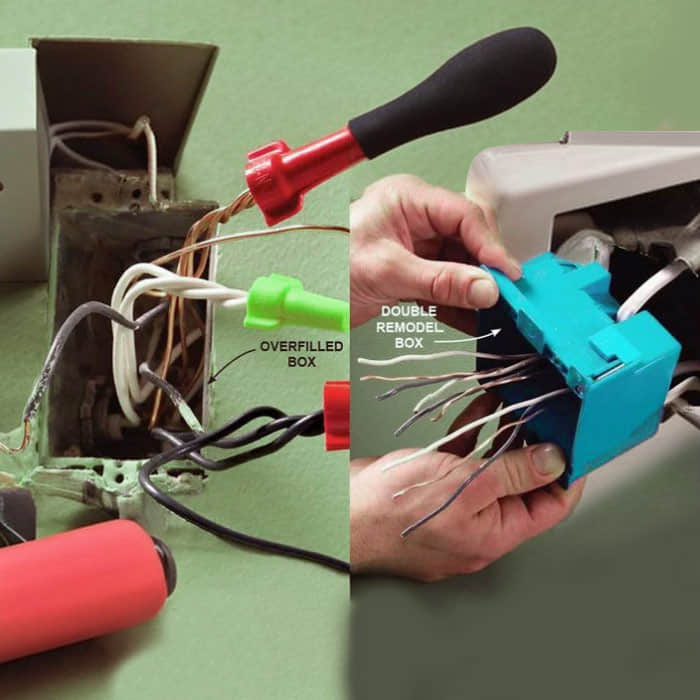

Mistake: Box too small

This mistake refers to the use of an inadequate box size when accommodating multiple wires and devices. When there are too many wires stuffed into a small box, it can result in overheating, short-circuiting, and potential fire hazards. The National Electrical Code specifies minimum box sizes to minimize these risks.

Solution: Install a larger box

The suggested solution involves calculating the minimum box size required based on the number of wires and components present. To determine the minimum box size, the following items should be considered:

Each hot wire and a neutral wire entering the box count as 1.

All ground wires combined count as 1.

All cable clamps combined count as 1.

Each device (switch or outlet, excluding light fixtures) counts as 2.

The total is then multiplied by 2.00 for 14-gauge wire or by 2.25 for 12-gauge wire to determine the minimum box size required in cubic inches. It is essential to select a box with at least this much volume to accommodate the wiring safely.

Plastic boxes typically have the volume stamped inside, often located on the back. Steel box capacities are listed in the electrical code and may require measuring the height, width, and depth of the interior to calculate the volume accurately.

Reversing Hot and Neutral Wires

Mistake: Wires reversed

This mistake refers to the incorrect connection of the black hot wire to the neutral terminal of an outlet. This reversal creates a hazardous situation where there is a potential for a lethal electric shock. It can be difficult to detect this mistake initially, as lights and other devices may still function, albeit unsafely.

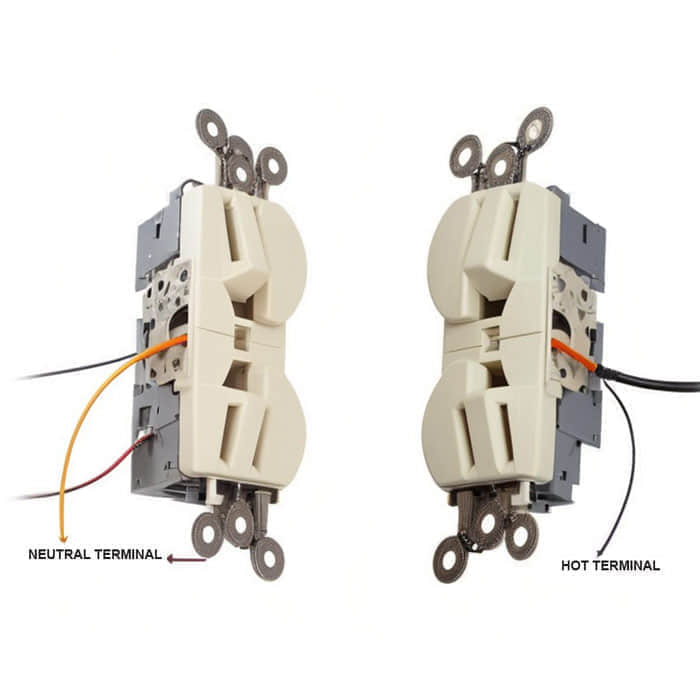

Solution: Identify the neutral terminal

The suggested solution emphasizes the proper connection of wires to ensure safety. When wiring outlets and light fixtures, it is crucial to always connect the white wire, which represents the neutral wire, to the neutral terminal. The neutral terminal is typically marked and can be identified by a silver or light-colored screw.

Additionally, the hot wire, usually black, should be connected to the other terminal. If there is a green or bare copper wire, it indicates the ground wire. The ground wire should be connected to the green grounding screw or a designated ground wire or grounded box.

Wiring a GFCI Backward

Mistake: Outdated wiring

This mistake highlights the presence of outdated wiring in a home, which may not provide adequate electrical safety measures. Outdated wiring systems may lack the necessary protective features, such as GFCI outlets, which can pose a risk of electric shock.

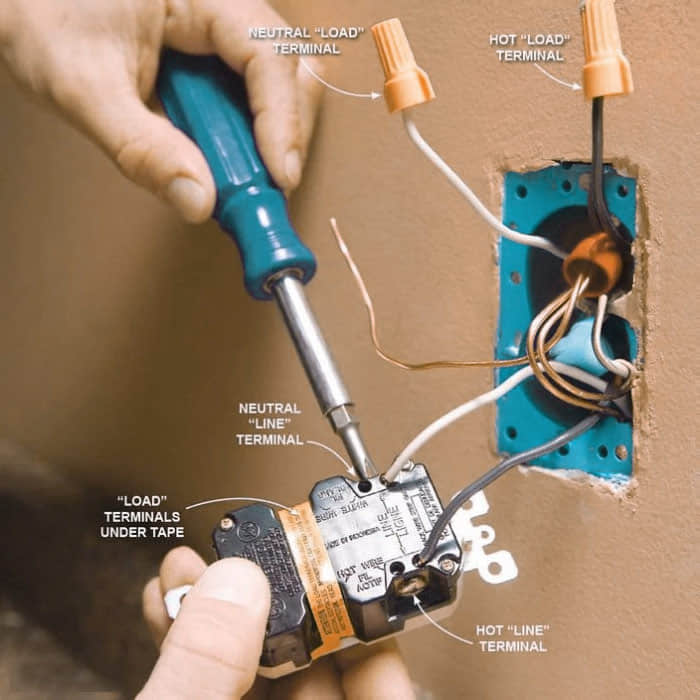

Solution: Connect power to the ‘line’ terminals

The suggested solution focuses on the proper installation of GFCI outlets. These outlets typically have two pairs of terminals. The ‘line’ terminals are specifically designed to receive incoming power for the GFCI outlet itself. The other set of terminals, labeled ‘load,’ is intended to protect downstream outlets.

To ensure effective shock protection, it is crucial to connect the power source to the ‘line’ terminals of the GFCI outlet accurately. Mixing up the ‘line’ and ‘load’ connections can result in a loss of shock protection. Therefore, attention should be given to correctly identifying and connecting the wiring.